welcome to AirMotor

We manufacture a wide range of standard & bespoke Air Motors in the UK for a huge variety of applications.

Typical applications include high torque Air Motors for drilling or low torque, high speed handheld Air Motors for mixing and spraying.

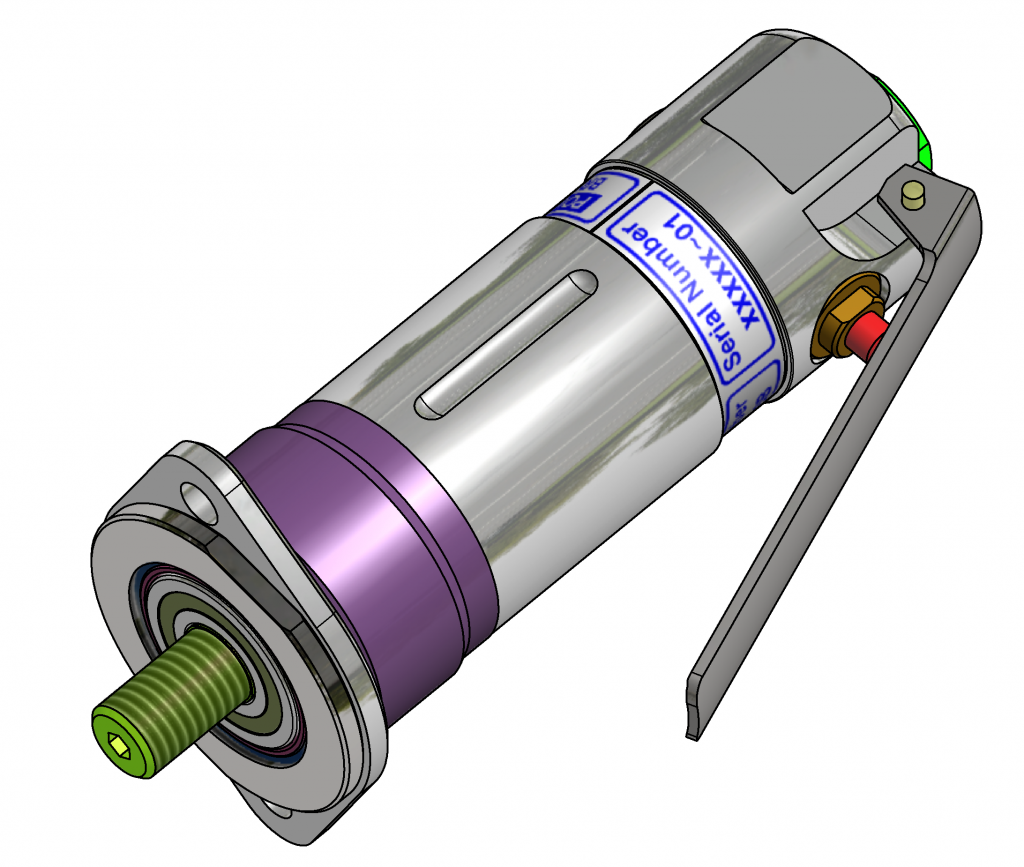

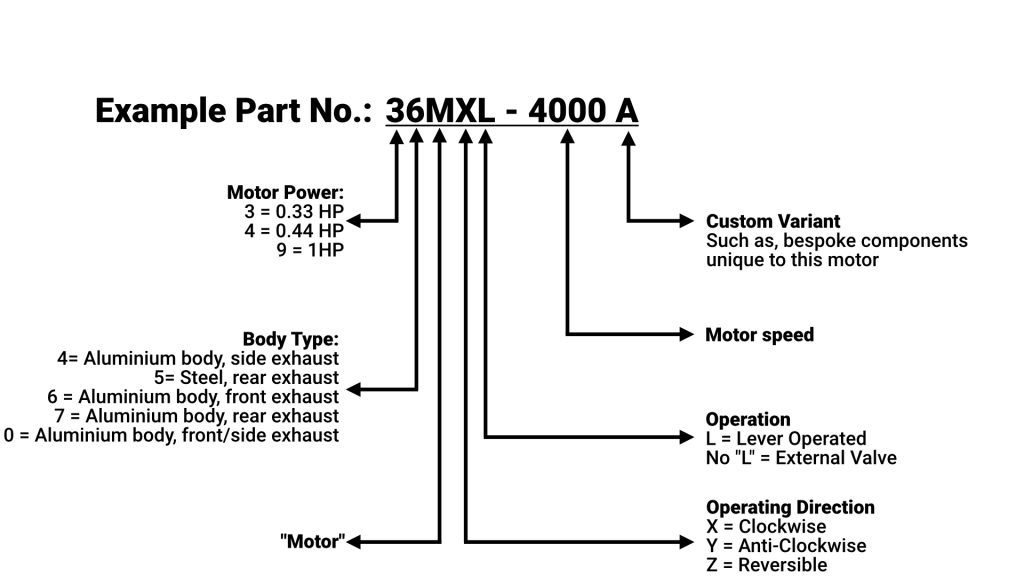

This includes the 36ML-4000 and the 35MX-4100.

We design and manufacture Air Motors for OEMs. We understand and solve problems such as mounting and valving.

Benefits include:

- High power-to-weight ratio

- Lubrication free operation available

- Stainless steel motors and components available

- Tough and versatile design

- No spark operation

- Can be stalled or overloaded without any damage.

- Capable of repeated ON/OFF cycles

- Special delta-profile motors are available for maximum power in really tight spaces

- Simple speed/torque control by means of pressure and flow regulators.

A Unqiue Product

We provide a bespoke Air Motor product and service like no other. This is achieved by combining our in-house technical capabilities with our understanding of how the product is used in the field.

Whilst we have a range of standard motors available, we appreciate the need for compatibility. Therefore, we offer a range of custom components such as air inlets, custom output shafts and flanges. Additionally, we offer different materials, such as stainless steel & aluminium air motors.

A Unqiue Service

To truly ensure that the Air Motors we build are of the highest quality, we built a bespoke test rig. By using a set of predefined test specifications, we put each and every motor through it’s paces.

If it doesn’t pass our test, it’s not good enough!

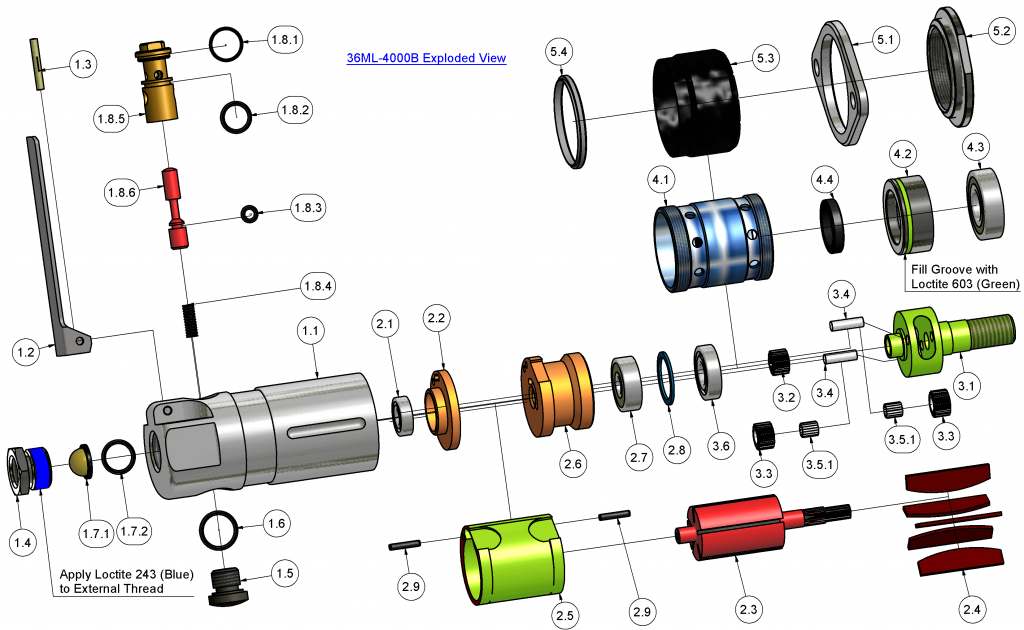

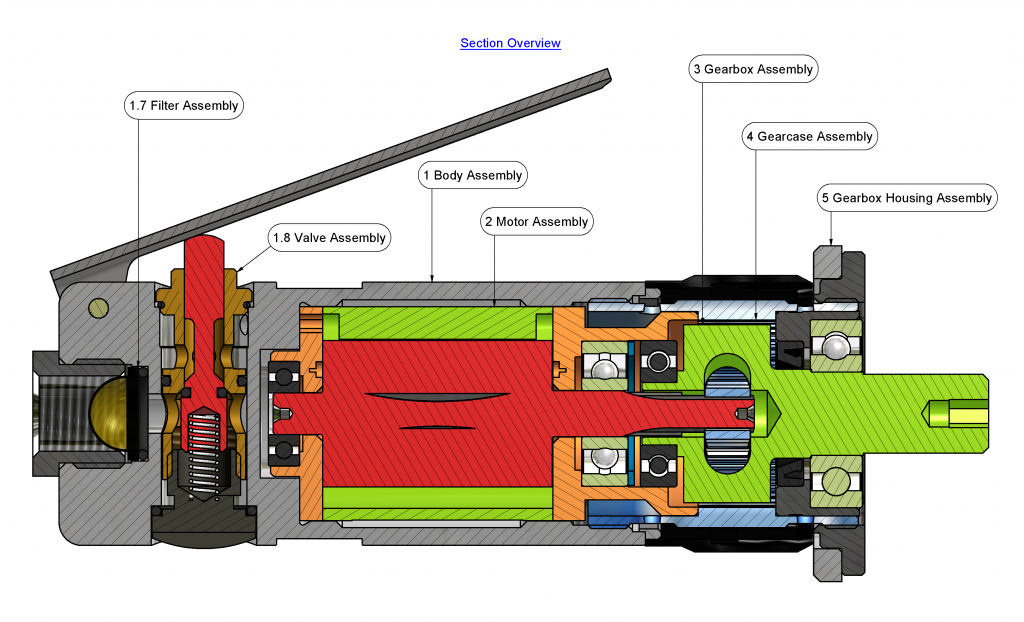

Air Motor Support and Spares

Some of our Air Motors have hard lives and after many years in operation can require servicing. We stock a huge range of spare and replacement parts for current and legacy products.

We also offer repair and refurbishment in-house which includes a full test to ensure your motor performs exactly as it should.

Our Standard Range Of Air Motors

34 Series Air Motors

35 Series Air Motors

35MZ-880

High torque, medium speed and lever-less multi-direction Air Motor with lube-free operation.

35MZ-2100

Medium torque, high speed and lever-less multi-direction Air Motor with lube-free operation.

35MY-2200

Medium torque, high speed and lever-less multi-direction Air Motor with lube-free operation.

35MX-4100

Low torque, high speed and lever-less

multi-direction Air Motor with

lube- free operation.

36 Series Air Motors

36ML-500

High torque Air Motor with 2 stage valve, 5mm auxiliary/ ’dead mans valve’ and adjustable speed control.

36ML-2500C

Medium torque Air Motor with 2 stage valve, 5mm auxiliary/ ’dead mans valve’ and adjustable speed control.

36ML-2500M

Medium torque Air Motor with 1 stage valve and stainless steel components.

36ML-4000C

Low torque, high speed front exhausting Air Motor with 1 stage valve, 2 hole flange mount and metric output shaft

37 Series Air Motors

37ML-4000

Low torque, high speed rear exhausting Air Motor with 1 stage valve, 2 hole flange mount

and metric output shaft

44 Series Air Motors

90 Series Air Motors

90MX-800

Ultra high torque, medium speed, front exhausting Air Motor with a range of mounting flanges available.

Air Motor Part Number Breakdown

Air Motor Typical Applications

Example applications of our air motors include:

- Specialised drilling, tapping and milling units especially in hostile environments

- Material chopping units

- GRC & GRFC mixed spraying

- Bespoke milling machinery operation

- Thermal, Metal and Arc Spray

- Petrochemical

- Paper, Nuclear

- Portable tools

- CNC machining/routing units

- Metering pumps

- Stitching guns

- Resin mixing

- Ink pumps

- Screw and belt conveyors

- Clamping

- Injection moulding

- Stirring, sawing, paint mixing, spooling

Air Motor Technical Specifications

Our varied range of air motors can include the following features:

- Power from 0.1-5kw

- Speeds from 30-20,000rpm

- Torque up to 300Nm

- Output shafts from 4mm upwards:

- plain with or without keyway, tapped shaft, threaded shaft, stepped shaft, male hexagon, female hexagon, square, splined etc.

- Custom output shafts available

- Mountings available are flange with or without holes, threaded or clamped, threaded bodies, ring nut. Custom mounting options available

- Direct inlet or Lever operation

- Exhaust – silenced, to atmosphere or piped

- Lubricated or dry air operation

- Control valves, Filters, Regulators, Lubricators, and fittings whether special [for example with safety features] or standard off-the-shelf.

- In-house label printing with serial numbering + customer’s logo and model number at no additional cost.